Views: 0 Author: Site Editor Publish Time: 2025-07-23 Origin: Site

Refractory anchors play a key role in securing refractory linings inside high-temperature equipment. These specialized fasteners connect refractory material—such as bricks, castables, or ceramics—to the metal structure of furnaces, kilns, and boilers. Their design helps maintain the stability of refractory linings, especially in high-heat environments where thermal expansion and contraction can cause shifting or damage. The importance of refractory anchors becomes clear in industries like steel, cement, and petrochemical, where high-temperature applications require reliable support for refractory linings.

Refractory anchors:

Provide stability and support to refractory linings, preventing cracking or dislodgement.

Distribute mechanical and thermal stresses across the lining.

Resist corrosion and maintain strength in high temperature and harsh conditions.

Allow for easier installation and maintenance.

Proper selection ensures long service life for refractory linings and protects equipment in demanding high-temperature and high-heat environments.

Refractory anchors secure high-temperature linings, preventing damage from heat and movement.

Different anchor types like V-shaped, Y-shaped, zig-zag, and spiral suit various industrial needs.

Choosing the right anchor material, such as stainless steel or ceramic, ensures durability and safety.

Proper installation and regular inspection of anchors extend equipment life and reduce costly repairs.

Following industry standards and expert advice helps maintain efficient and safe high-heat operations.

Refractory anchors come in many shapes and designs, each serving a specific purpose in high-temperature environments. The choice of anchor depends on the lining material, expected thermal movement, and the operating conditions of the equipment. The main types of refractory anchors include V-shaped, Y-shaped, zig-zag, and crook or spiral anchors. These anchors help secure refractory linings, distribute stress, and extend the service life of industrial furnaces, kilns, and boilers.

V-shaped anchors are among the most common types of refractory anchors used in industry. Manufacturers often produce these anchors from high-temperature alloys such as stainless steel or Inconel. V-shaped anchors provide strong mechanical support and resist corrosion, making them suitable for environments with high heat and chemical exposure.

| Aspect | Details |

|---|---|

| Typical Applications | Steel mills, power plants, cement kilns, petrochemical reactors, incinerators |

| Advantages | Corrosion resistance, high-temperature stability, mechanical strength, versatility, long service life |

| Operational Benefits | Maintains lining integrity, prevents sagging or cracking, enhances safety, optimizes heat transfer, extends equipment life |

V-shaped anchors work well in furnaces, boilers, and chimneys. Their design helps prevent refractory displacement under stress or vibration. These anchors also reduce maintenance needs by keeping linings stable for longer periods.

Y-shaped anchors offer another reliable solution for securing refractory linings. These anchors distribute load evenly across the lining, which helps prevent cracking or displacement. Manufacturers use materials like Stainless Steel 321 or Inconel to ensure durability and resistance to high temperatures.

Y-shaped anchors are common in furnaces, boilers, and kilns found in petrochemical, cement, and steel industries. Their shape provides structural integrity and prevents material slippage, even during thermal cycling. Custom designs and sizes allow Y-shaped anchors to fit a wide range of installation needs, making them a versatile choice for many industrial processes.

Tip: Y-shaped anchors are especially useful for monolithic refractory anchors, where even load distribution is critical for thick or heavy linings.

Zig-zag anchors stand out for their superior holding power and ability to withstand extreme thermal and mechanical stresses. Their intricate shape gives them an advantage in high-temperature environments where standard anchors might fail. Although zig-zag anchors cost more due to their complex manufacturing process, their performance justifies the investment in demanding applications.

These anchors are ideal for situations where the refractory lining faces frequent temperature changes or heavy mechanical loads. Zig-zag anchors help maintain the stability of the lining, reducing the risk of failure in critical equipment.

Crook and spiral anchors provide dependable performance in harsh industrial settings. Manufacturers use high-quality stainless steel grades such as 304, 316, 310, and 321 to produce these anchors. Their design offers excellent tensile strength, corrosion resistance, and stability at elevated temperatures.

Crook and spiral anchors are widely used in industries like power generation, oil and gas, chemical processing, pharmaceuticals, and desalination. Their sturdy construction and resistance to stress corrosion, cracking, and oxidation make them suitable for supporting refractory linings in equipment exposed to aggressive conditions.

Note: Modular anchors, including crook and spiral types, can be customized to fit specific installation requirements, ensuring precise support for various lining materials.

The selection of refractory anchors depends on several factors, such as the type of refractory lining, expected thermal expansion, and the operating environment. Proper anchor choice ensures mechanical stability, accommodates thermal movement, and optimizes the service life of the refractory lining.

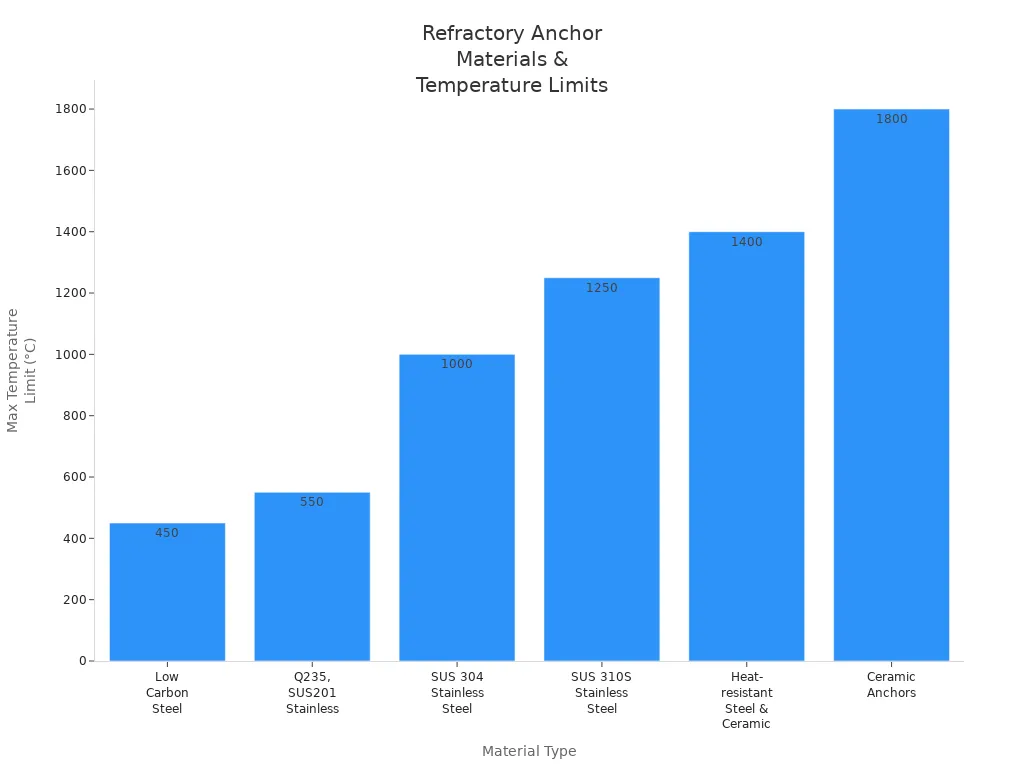

Selecting the right materials used for refractory anchors is essential for performance in high temperature environments. The choice of material affects not only high-temperature resistance but also corrosion resistance and mechanical strength. These properties determine how well anchors support refractory linings and how long they last in harsh industrial settings.

Stainless steel refractory anchors are the most common choice for many industries. Grades like 304, 310S, and 330 provide a strong balance of corrosion resistance and high-temperature resistance. Stainless Steel 304, known for its chromium and nickel content, offers excellent strength and ductility. Stainless Steel 310S maintains structural integrity and resists corrosion even in extreme heat, making it ideal for furnaces and boilers. Stainless Steel 330 stands out in moist or humid environments, where it prevents rust and maintains holding power. These anchors can handle temperatures from 550°C up to 1250°C, depending on the grade.

| Material Type | Temperature Limit (°C) | Notes |

|---|---|---|

| SUS 304 Stainless Steel | 550 - 1000 | Widely used stainless steel |

| SUS 310S Stainless Steel | 1000 - 1250 | Higher temperature stainless steel |

| Stainless Steel 330 | 1100 - 1150 | Superior corrosion resistance in humid environments |

ASTM C 863 sets the standards for metallic refractory anchors, ensuring that stainless steel refractory anchors meet strict requirements for strength, durability, and safety.

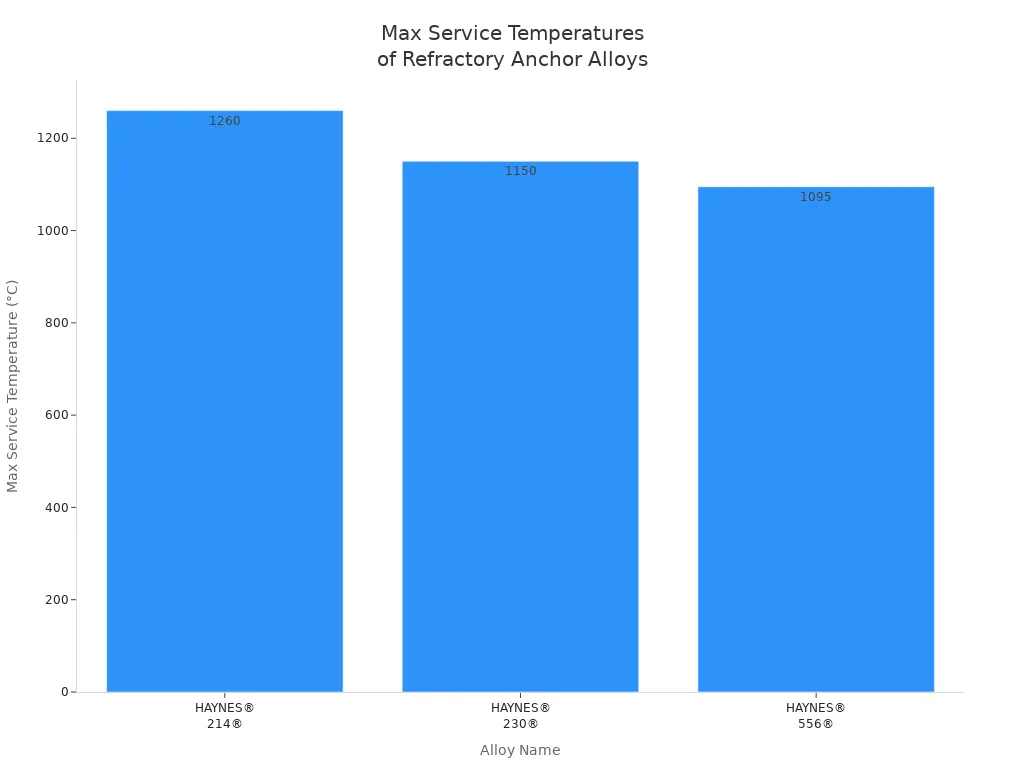

Alloy steels extend the performance of refractory anchors in even more demanding conditions. Advanced alloys such as HAYNES® 214®, 230®, and 556® offer high-temperature resistance and exceptional mechanical strength. These alloys resist oxidation, carburization, and sulfidation, making them suitable for aggressive chemical environments.

| Alloy Name | Max Service Temperature (°C) | Key Properties and Usage Context |

|---|---|---|

| HAYNES® 214® | 1260 | Excellent oxidation resistance, thermal stability, nitriding resistance |

| HAYNES® 230® | 1150 | High elevated temperature strength, oxidation and carbo-nitriding resistance |

| HAYNES® 556® | 1095 | Exceptional strength in sulfur-bearing, carburizing, and aggressive environments |

Manufacturers rely on ASTM C 863 to select alloy steels that guarantee anchors will withstand thermal cycling and corrosive atmospheres.

Ceramic anchors provide the highest level of high-temperature resistance, withstanding temperatures up to 1800°C. These anchors, made from clay, high alumina, or corundum, excel in environments where metal anchors would fail. Ceramic anchors resist chemical erosion and maintain stability in the most extreme heat. They are often used in furnaces, kilns, and reactors that operate at the upper limits of industrial temperatures.

ASTM C 863 guides the selection of metallic anchors, but for the highest temperatures, ceramic anchors become the preferred solution.

Refractory anchors serve as essential components in many high-temperature applications. Their main role is to stabilize refractory linings and protect equipment from damage. The following sections highlight how different industries use these anchors to ensure safety, efficiency, and long service life.

Furnaces and kilns operate under extreme heat and mechanical stress. Refractory anchors secure refractory linings inside these units, preventing movement caused by thermal expansion or contraction. Manufacturers use anchors made from stainless steel, carbon steel, or special alloys to withstand harsh conditions.

They maintain the integrity and durability of refractory linings by holding materials in place.

Anchors distribute loads and prevent slippage or dislodgment.

Their placement forms a support network that resists erosion, thermal cycling, and mechanical stress.

By anchoring refractory materials, they help maintain insulation and heat containment, which extends the lifespan and safety of furnaces and kilns.

Properly installed refractory anchors reduce maintenance needs and help avoid costly repairs in high-temperature applications.

Boilers and incinerators rely on refractory anchors to keep refractory linings stable during operation. These environments face rapid temperature changes and exposure to corrosive gases.

Anchors hold refractory linings in place, preventing shifting or detachment.

They support the lining, which shields equipment from thermal damage and corrosion.

The right design and material selection ensure durability and reliability.

Regular inspection and maintenance of anchors and linings help prevent equipment failure and reduce downtime.

Refractory anchors play a vital role in maintaining the integrity of refractory linings in boilers and incinerators. When anchors fail, linings can degrade quickly, leading to expensive repairs and operational interruptions.

Cement and petrochemical plants present some of the most challenging environments for refractory linings. Equipment in these industries faces chemical attack, thermal shock, mechanical wear, and moisture infiltration.

Refractory anchors secure linings in high-temperature equipment such as cement kilns and petrochemical reactors.

They help maintain the durability and integrity of linings exposed to extreme heat and chemicals.

Anchors stabilize linings against mechanical and thermal stresses, reducing the effects of corrosion and wear.

Proper installation and maintenance, following standards like API 936, ensure lining stability and operational efficiency.

These practices help reduce downtime and improve the performance of high-temperature applications in cement and petrochemical plants.

Many other industries benefit from the applications of refractory anchors. The table below shows common uses across several sectors:

| Industrial Sector | Common Applications of Refractory Anchors |

|---|---|

| Construction | Anchoring large concrete structures such as bridges, dams, and high-rise buildings to ensure stability and safety. |

| Oil and Gas | Securing offshore platforms, pipelines, and drilling rigs to withstand marine forces like currents and waves. |

| Power Generation | Stabilizing heavy machinery including turbines, generators, and transformers to prevent vibrations and damage. |

| Mining | Supporting underground mining equipment, tunnels, ventilation systems, and conveyor belts for operational safety. |

| Manufacturing | Anchoring large machines such as presses, stamping equipment, and robotic systems to enhance efficiency and safety. |

These examples show the versatility of refractory anchors in supporting refractory linings and protecting equipment in a wide range of high-temperature applications.

Refractory anchors play a vital role in holding refractory linings in place inside high-temperature equipment. In cement plants, boilers, and kilns, these anchors prevent refractory material from falling or detaching, even when exposed to extreme heat. Refractory concrete anchors, such as V-shaped or Y-shaped designs, provide strong mechanical support. They keep the lining stable and help maintain operational reliability. By securing the refractory lining, anchors ensure that the equipment operates safely and efficiently.

Proper installation of refractory anchors helps maintain the structural integrity of refractory linings and extends the service life of industrial equipment.

Anchors protect refractory linings from damage caused by thermal expansion, vibration, and chemical attack. Welded to the steel shell, they stop refractory material from shifting or collapsing. If anchors corrode or fail, the lining can fall away, exposing the metal shell to hot gases. This exposure can lead to overheating and costly repairs. Regular inspection and timely replacement of damaged anchors are essential for maintaining reliability and preventing early failure. High-quality anchors resist corrosion and embrittlement, even in harsh environments with volatile substances.

Anchors reduce the risk of sagging, cracking, or detachment.

They help maintain a continuous lining, which improves heat transfer and efficiency.

Reliable anchoring systems protect both the refractory lining and the equipment shell.

Refractory anchors support a wide range of refractory materials, including castables, bricks, boards, and fiber modules. The design and size of the anchor depend on the type and thickness of the lining. For example, Y-shaped anchors work well with thick linings, while V-shaped anchors suit thinner applications. Corrugated anchors handle areas with frequent thermal cycling. Anchor materials, such as stainless steel or heat-resistant alloys, match the thermal expansion of the refractory material to prevent stress and damage.

Refractory anchors support castables, ceramic fibers, and refractory bricks.

Anchor design varies based on lining thickness and operating conditions.

Proper anchor selection ensures compatibility and long-term performance.

The uses of refractory anchors highlight their versatility and importance in maintaining the safety and efficiency of high-temperature industrial processes.

Refractory anchor systems form the backbone of stable refractory linings in industrial equipment. These systems combine different anchor types, materials, and installation methods to keep linings secure during operation. Each component works together to prevent shifting, cracking, or falling of the refractory lining, even under harsh conditions.

| Anchor Type | Material | Key Function / Role in Lining Stability |

|---|---|---|

| V-Shaped | Stainless steel or heat-resistant materials | Provides strong mechanical support; simple and effective design |

| Y-Anchors | Stainless steel or heat-resistant materials | Offers strong support and durability in high-temperature environments |

| Stud Anchors | Metal studs welded to base plates | Secure refractory linings to metal surfaces; withstand mechanical stress |

| Spiral Anchors | Heat-resistant materials | Accommodate thermal expansion and contraction to prevent damage |

| Knurled Anchors | Various materials with textured surface | Enhance grip to prevent slippage under vibration or mechanical stress |

Designing effective refractory anchor systems requires careful planning. Engineers must select anchor materials that match the operating temperature and chemical environment. Stainless steel, nickel alloys, and carbon steel are common choices. Anchor design depends on the type of refractory, expected mechanical stresses, and the thickness of the lining. Proper anchor spacing, embedment depth, and pattern help distribute loads and prevent stress concentrations.

A well-designed system allows for thermal expansion and contraction. Protecting anchor tips with plastic caps or coatings helps prevent cracks. Regular inspection and maintenance keep the system reliable. Inspections should occur during scheduled shutdowns or with remote thermal imaging. Maintenance plans may include quarterly or annual checks, depending on equipment use.

Selecting the right refractory anchor systems involves several key steps:

Match anchor material to the highest expected temperature. For high temperature, use grades like T310 stainless steel or Incolloy 601.

Choose anchor type based on lining thickness. Wire anchors suit linings under 9 inches, while ceramic anchors work best for thicker linings.

Size anchors to reach 75%-85% of the lining thickness, keeping tips close to the hot face.

Design anchor spacing and pattern to fit equipment geometry and reduce stress.

Use coatings or floating anchors to allow for movement and prevent cracking.

Ensure qualified installers handle welding and fastening.

Maintain a regular inspection schedule to catch issues early.

Tip: A robust refractory anchor system maintains lining stability, even if cracks develop, and extends equipment life in high-temperature applications.

Refractory anchors come in metallic and ceramic types, each chosen based on lining thickness, temperature, and application. Stainless steel and Inconel anchors, such as V-anchors and Y-anchors, support linings in furnaces and kilns, while ceramic anchors handle extreme heat. Proper anchor selection and placement prevent failures, reduce maintenance, and extend equipment life.

Following ASTM and API936 standards ensures anchors withstand stress and corrosion.

Consulting experts and using quality materials help maintain safety and efficiency in high-temperature environments.

Choosing the right anchor system protects both the refractory lining and the equipment, avoiding costly downtime and repairs.

Refractory anchors hold refractory linings in place inside high-temperature equipment. They prevent the lining from shifting, sagging, or falling. This support helps protect the equipment and ensures safe, efficient operation.

Experts recommend inspecting refractory anchors during every scheduled maintenance shutdown. Regular checks help spot corrosion, wear, or damage early. Early detection prevents costly repairs and equipment failure.

Manufacturers advise against reusing refractory anchors. Removal can weaken the anchor or cause hidden damage. New anchors provide better safety and performance for each installation.

| Standard | Description |

|---|---|

| ASTM C 863 | Sets requirements for metallic anchors |

| API 936 | Covers refractory installation in industries |

These standards ensure anchors meet safety and quality guidelines.